Plate Heat Exchanger Specifications by Model

|

Model |

A |

B |

C |

D |

F |

H |

Weight |

Volume per Channel |

Unit Heat Exchanger Area |

Design Pressure |

Refrigeration Capacity |

Max Number of Plates |

Max Connection Size |

mm |

kg |

Liters |

m2 |

Mpa |

KW |

B3-5A |

135 |

40 |

104 |

18 |

5 |

4.7+1.8xNP |

0.04+0.0021xNP |

0.006 |

0.005 |

3.0 |

1-5 |

30 |

1/4" NPT |

B3-12A |

199 |

85 |

154 |

40 |

7 |

13+2.34xNP |

0.4+0.044xNP |

0.018 |

0.012 |

1.0 |

1-6 |

60 |

3/4" NPT

7/8" Welded |

B3-14DW |

196 |

86 |

156 |

46 |

7+2.35xNP |

0.4+0.096xNP |

0.022 |

0.014 |

B3-16A |

220 |

90 |

180 |

52 |

7+2.24xNP |

1.1+0.06xNP |

0.029 |

0.016 |

2-8 |

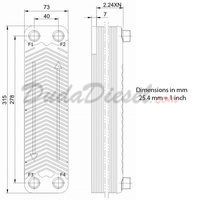

B3-23A |

315 |

73 |

278 |

40 |

1.2+0.07xNP |

0.040 |

0.023 |

3-10 |

B3-27A |

286 |

116 |

234 |

63 |

7+2.4xNP |

1.3+0.125xNP |

0.050 |

0.027 |

3.0 |

5-20 |

120 |

1-1/4" NPT |

B3-32A |

243 |

72 |

1.3+0.126xNP |

0.032 |

1" NPT

1-1/8" Welded |

B3-32DW |

10+2.42xNP |

1.3+1.52xNP |

B3-36A |

466 |

73 |

432 |

40 |

7+2.24xNP |

1.3+0.106xNP |

0.063 |

0.036 |

4-15 |

3/4" NPT

7/8" Welded |

B3-52A |

523 |

107 |

466 |

50 |

15+2.4xNP |

1.5+0.23xNP |

0.094 |

0.052 |

10-70 |

1" NPT

1-1/8" Welded |

B3-60A |

529 |

124 |

478 |

73 |

7+2.4xNP |

2.7+0.26xNP |

0.111 |

0.060 |

160 |

|

B3-63A |

390 |

200 |

298 |

120 |

7+2.55xNP |

5.5+0.27xNP |

0.128 |

0.063 |

B3-95A |

616 |

191 |

519 |

92 |

7+2.4xNP |

7.8+0.42xNP |

0.250 |

0.095 |

30-200 |

200 |

2" Threaded

2-1/8" Welded |

B3-105A |

528 |

246 |

430 |

148 |

9.5+0.46xNP |

0.290 |

0.105 |

2.0 |

280 |

3" Threaded |

B3-115A |

535 |

253 |

456 |

174 |

15+2.4xNP |

14+0.424xNP |

0.250 |

0.115 |

3.0 |

2" Threaded

2-1/8" Welded |

Conversion |

1" = 25.4mm |

1 kg = 2.2 lb |

1 Liter = 0.264 Gallons |

1m2 = 10.76ft2 |

1 Mpa = 145 psi |

1 KW = 3412 Btu/h |

|

|

General Specifications of Duda Energy Plate Heat Exchangers |

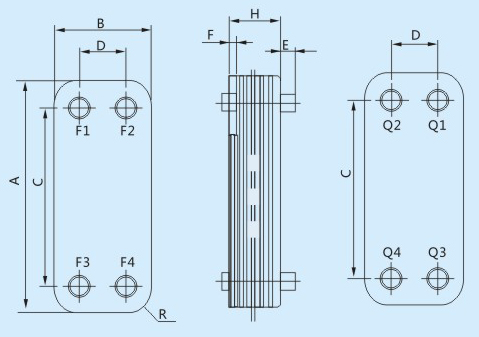

| Plate Material |

SUS304, SUS316 for Double Wall Units & Nickel Brazed |

| Welding Material |

B3=99.9% Copper, B4=99.9% Nickel |

| Mounting Studs |

B3-5A & B3-12A use M5-0.8, Larger units use M8-1.25 |

| Flow Direction |

A Type: F1-F3, F2-F4 |

| UL Listing |

TUVReinland ISO9001:2000 |

Corrosion:

304 Stainless Steel has good general corrosion resistance to a range of organic and in-organic fluids. It will have poor resistance to sulfuric and hydrochloric acids. Crevice corrosion may also occur when chlorides (salts) are present in the fluid. Since chlorides are in all natural sources of water it is best to use distilled water whenever possible. Typically, a unit will last about 10-15 years with regular tap water depending on salt content. With water containing chlorides or salt water, the life expectancy of the heat exchanger is reduced to about 3-5 years of continuous use, depending on the quality of the water. It is best to clean the units by back flushing with fresh water if highly contaminated fluids are used.

316 Stainless Steel is used in special applications where the working fluid may attack 304 stainless stee lmore aggressively.

Nickel brazed heat exchangers are designated with a B4 model code.They are used in applications where copper is not suitable for the working fluid. All nickel brazed heat exchangers use SUS316 plates.

Efficiency:

Use plate heat exchangers in a counter-flow configuration for highest efficiency. This allows the possibility of the cold fluid exit temperature to reach the temperature of the hot fluid inlet temperature.

Plate heat exchangers mostly utilize convection for their efficiency. Faster flow rates with more contact time (length of unit) will result in higher efficiency. More plates and more width is used mostly for reducing pressure drop through the units. While more plates or an increase in the width of the plates may add some additional efficiency, it is due to more surface area contact and less velocity through the plus, thus reducing convection efficiency. Always choose a unit with more length for more efficiency unless less pressure drop is crucial.

If you have a specific application with specific requirements to meet, it is recommended to fill out a sizing request on our heat exchanger sizing form.

Custom Heat Exchangers:

For model/plate/fitting combinations which we do not normally stock, we can also produce custom units with some lead time.Contact us for details.

|